IMPACT TEST

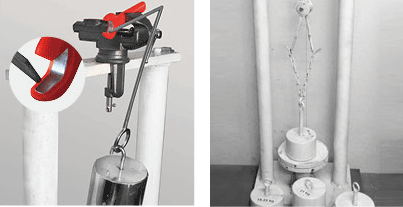

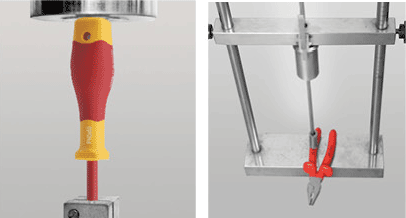

There are two tests carried out: The first test is performed at an ambient of -25±3°C(the tools lay in a cold chamber for 2 hours), if with C marked test need to be done by -40±3°C and is carried out 120 seconds after the tools have been removed from the chamber. The second test is carried out at ambient temperature of 23±5°C. The hammer is allowed to fall freely on three different places of the insulated material. The test piece is acceptable if t he handle is not cracked, broken or does not show signs of faking. This test can be compared to a fall of the tool from a height of 0.6m at a temperature of -25°C and a fall from a height of 2m at room temperature